I-GUSEN ikuzisa ukuba ukwazi ulwazi olufanelekileyo lwe-anchor yokuzisika, enokunciphisa ingxolo ngexesha le-welding.Ngenxa yokubambisana okukhulu phakathi kwebholiti kunye nepleyiti yensimbi, ngoko ke ngexesha le-welding, akukho ngxolo iya kuveliswa.Kwaye ngenxa yokuba ixesha le-welding lifutshane, ngoko aliyi kuchaphazela umatshini wonke.Ukongezelela, ukuphulwa kwentambo kunokuphetshwa kwinkqubo ye-welding.Ngale ndlela, ukusebenza kakuhle kwe-incision kuphuculwe kakhulu.Xa kungekho nxu lumano phakathi kwebholiti ye-ankile ephantsi yokuzisika kunye nepleyiti yentsimbi, akukho msebenzi wezandla ofunekayo kuba akukho nxibelelwano phakathi kwe nut kunye nepleyiti yentsimbi.Inkqubo ye-welding ye-anchor ephantsi yokuzisika iyathula kwaye ikhawuleza ngaphandle kokusebenza ngesandla.Kwinkqubo ye-welding ye-self-cutting bolt ye-anchor bolt, ukusebenza kwe-manual akufuneki xa i-nut kunye ne-plate yensimbi ingaxhunywanga kunye okanye xa i-nut kunye ne-plate yensimbi ingaxhunywanga.

Abavelisi beebholiti ze-anchor zokuzisika, umsebenzi weebhotshi zokusika ngokuzenzekelayo kukuqinisekisa ukuba akukho mntu usebenza kwiprojekthi yokufakela.I-bolt yokuzisika ingaba kwindawo echanekileyo ukwenzela ukuba i-anchor ayikwazi ukuqiniswa.Xa igxininiswe kwi-torque ekhulayo, iqinisekisa ukuba akukho kukhulula phakathi kwebholiti kunye ne-nut.Umsebenzi we-bolt yokusika ngokuzenzekelayo kukuqinisekisa ukuba akukho nto ikhululekile phakathi kwebholiti kunye ne-nut.Iinzuzo eziphambili zomatshini ziquka ukusetyenziswa kwentonga engcono yokudibanisa intonga yokuqinisa iteknoloji.Ngethuba lenkqubo yokufakela, ixesha le-welding lifutshane ngenxa yamandla amakhulu okuqinisa i-nut chain chain.Kwinkqubo yofakelo, ngenxa yokuqina okukhulu kokuqina kweebholiti ze-anchor chain, ukuze ubude be-weld kunye nezinye iingenelo.Kwinkqubo yofakelo, ngenxa yamandla amakhulu okuqinisa i-anchor chain bolts kunye nobude be-weld kunye nezinye izibonelelo.Sisebenzise inkqubo yoyilo ekhethekileyo ukuphumeza oku.

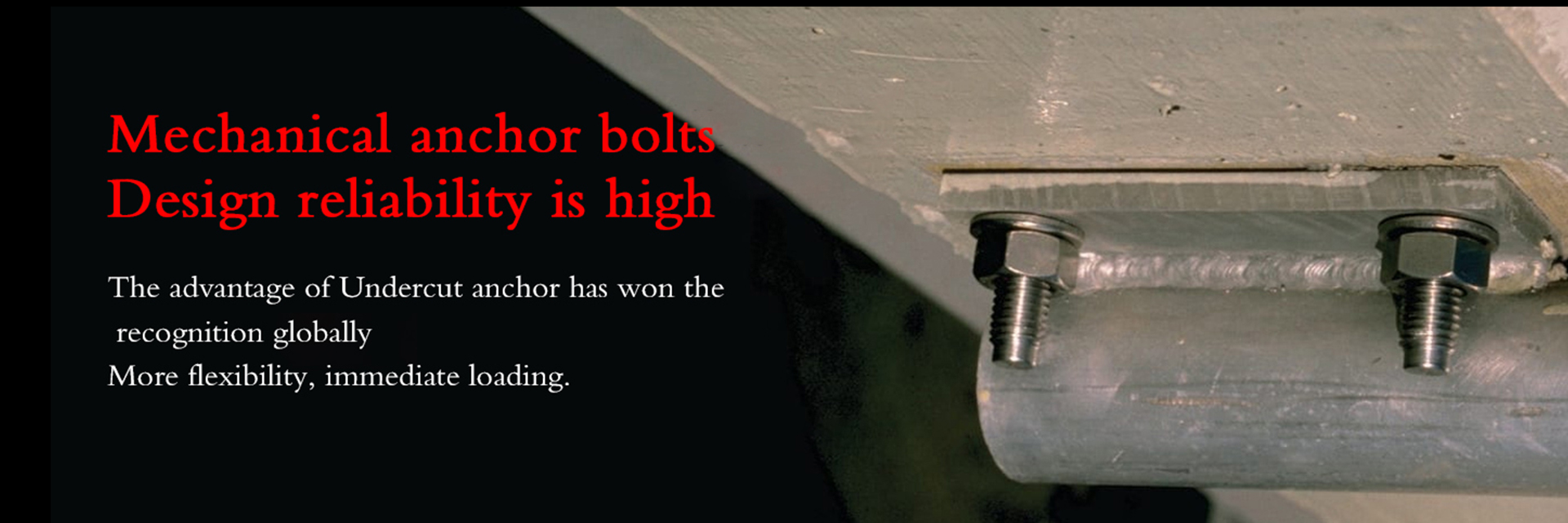

I-self-expanding mechanical anchor ingakanani imali, emva kokufakwa kwe-nut kusetyenziso oluqhelekileyo, inokuqiniswa ngokuthanda, ayiyi kubangela ukuphuka ngenxa yokwakheka okwahlukileyo kwe-anchor nut.Emva kokufakwa kwe-nut kwinkqubo yokusetyenziswa, inokuthi iguqule ngokuzenzekelayo, ilungise i-bolt kunye nomgca wokumisa.Ukuba kuyimfuneko ukutshintsha i-screws okanye ukubuyisela umgca womhlaba, kunokwenziwa kwakhona ngokusebenzisa umbane owakhelwe ngaphakathi kumatshini.Ekusikeni, ubuchule obukhethekileyo bukwasetyenziswa ukukhusela ibholithi ukuba ingawi.Itekhnoloji, ephuhliswe kwaye ithengiswe nguSanyo, ithintela iibholiti ukuba zingawi ngexesha lofakelo.Inzuzo kukuba ubukhulu obuhlukeneyo beeplate zetsimbi bunokusetyenziswa.Iipleyiti zetsimbi zihlulwe omnye komnye.Uqhagamshelwano phakathi kwepleyiti yensimbi kunye nezinye iindawo kwenza i-welding ibe yomelele.

Ukusika i-ankile yomatshini wokuzisika, xa intambo yocingo kunye nentambo yocingo yaphuka, ibholithi yokusika esezantsi ezenzekelayo inokutsalwa kude.Xa ukuphuka kwenzeka phakathi kwendawo yebholithi ephantsi yokuzisika kunye nesikhundla se-cone, ibholithi ephantsi yokuzisika inokutsalwa ngaphandle.Indlela yokulungelelaniswa ngokuzenzekelayo kwendawo ye-cone kunye ne-cone position iqondwa ngokulungelelanisa ubude kunye nobubanzi phakathi kwentambo yocingo kunye nentambo yocingo.Umatshini unomsebenzi wokulungelelanisa ngokuzenzekelayo, unokulungelelaniswa nangaliphi na ixesha ngokweemfuno zomsebenzisi.Ukongeza, umatshini ukwamkela inkqubo yolawulo oluzenzekelayo kunye nenkqubo yolawulo lombane.Olu yilo luvumela amantongomane kunye neebholiti ezifakwe emzimbeni ukuba zisebenze kunye.Iibholiti ezifakwe phakathi kumzimba wemoto, indawo engezantsi yomnyango kunye nengaphakathi kwi-trunk ayikwazi ukuqinisekisa ukukhuselwa kuphela, kodwa idlala indima yokukhusela.

Ukuzisika abenzi be-anchor bemishini yokuzisika, ehambelana nokunciphisa ukungqubuzana phakathi kweebholiti.Ngelo xesha, ukungqubuzana phakathi kwe-screw kunye nocingo kungancitshiswa.Uxinzelelo kufuneka lufakwe kwiibholithi.Ukuba ukukhuhlana phakathi kwendongomane kunye nocingo kwindawo edibeneyo kuphezulu kakhulu, kufuneka kusetyenziswe amandla oxinzelelo.Oku kunokunciphisa ukungqubana phakathi kwebholiti kunye nocingo.Ekufakeni, kufuneka sinikele ingqalelo kule miba ilandelayo ye-nut ayinakunxiba.Ngenxa yokuba ayifuni nakancinci ukuphinda ibuyiselwe.Ekusetyenzisweni, iibholiti nazo zinokulungiswa kwisitya esikhulu sensimbi ye-cylindrical.Ngale ndlela, iziphene zokuqinisa iibholithi ziyagwenywa.Ukongeza, ukuze kuthintelwe ukukhulula i-nut, ukuwa kunye nezinye iingxaki, kukwayile ibholiti encinci yokuqinisa.Ngenxa yolwakhiwo olukhethekileyo lwebholithi kunye noyilo loyilo.

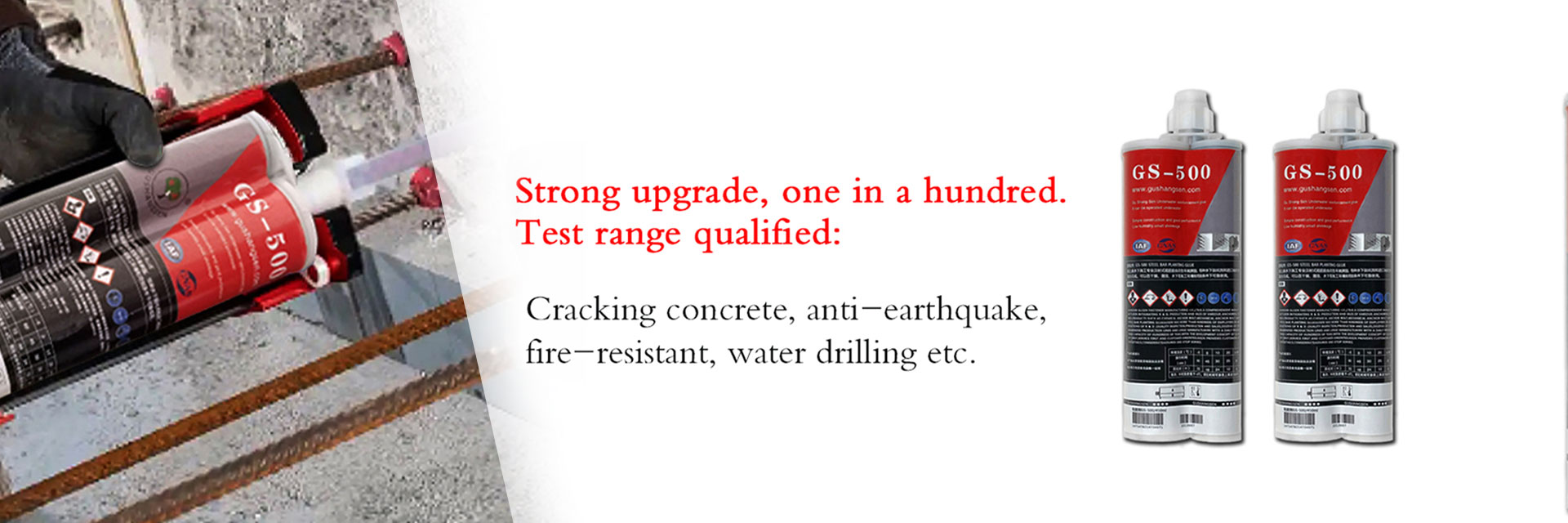

Yamkela itekhnoloji yokuwelda uxinzelelo oluphezulu.Obu buchule abunakwenza kuphela umzimba we-ankile kwaye i-bit yakha i-symmetrical structure kunye nokuzinza xa i-welding kwi-bolt.Eyesithathu kukusetyenziswa kobuchwephesha bokutywinwa kobushushu obuphezulu.Le teknoloji yenza ukungqubana phakathi kwebholiti kunye nentwana encinci, enokuthi ithintele ukukhuhlana phakathi kwe-ankile kunye nentwana.Kuxelwe ukuba le teknoloji ye-welding yoxinzelelo oluphezulu ifakwe kwaye idityaniswe yiteknoloji yokutywinwa kobushushu obuphezulu e-China, enenzuzo enkulu yezoqoqosho.Imveliso ibonakaliswe yindlela efanelekileyo yokuqinisa, enokuthi ilungise i-bolt nut kwi-bolt ngaphandle kokutshabalalisa ukubunjwa kwe-bolt nut xa i-bolt nut ine-self-cutting mechanical locking effect.Uyilo lunokuphucula ibhalansi phakathi kwekholamu ye-anchor kunye nokukhutshwa komhlaba kunye nokukhutshwa komhlaba.Isakhiwo seplate yensimbi siqiniswa, esenza ukuba isakhiwo seplate yensimbi sibe noqhagamshelwano oluhle kunye nomhlaba.

Ixesha lokuposa: Aug-18-2022