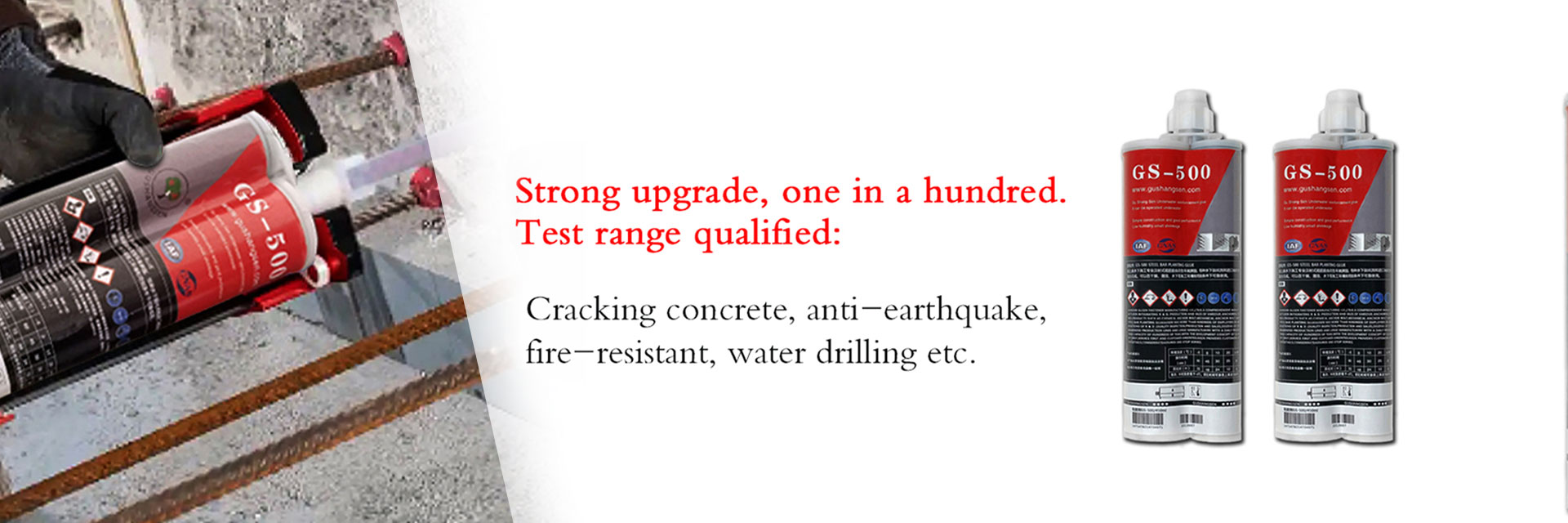

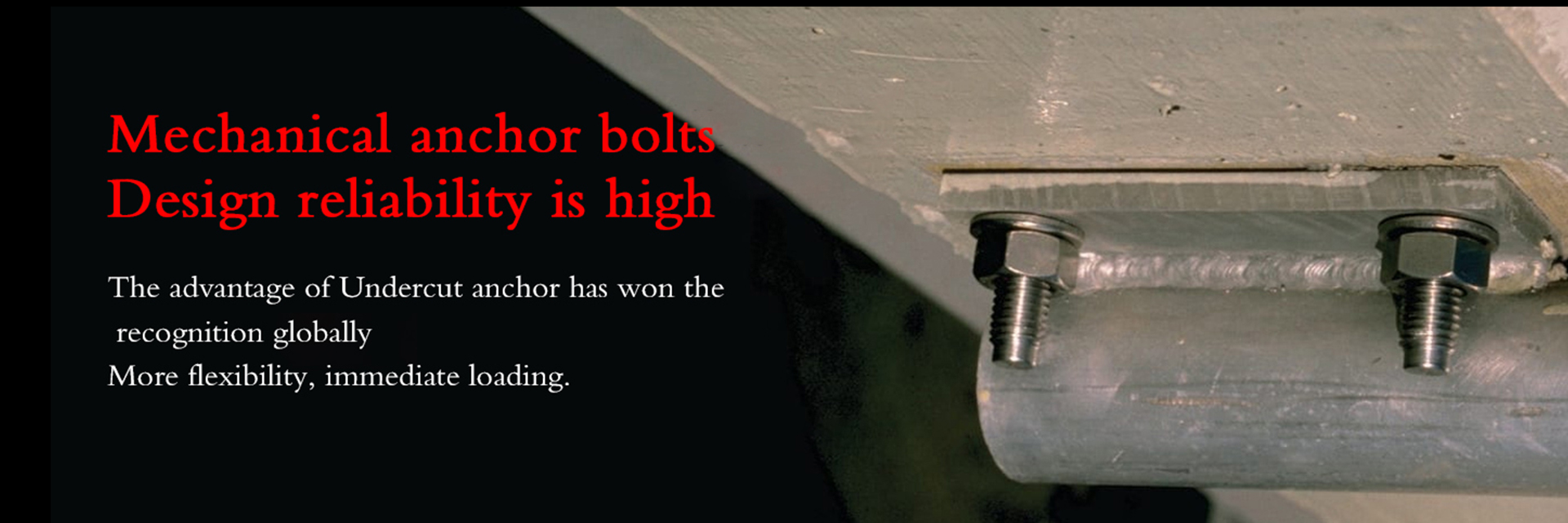

I-GUSEN iya kukunika ulwazi lwekowuteshini malunga neebholiti ze-anchor.i-anchor bolts zigxininiswe kwi-matrix yekhonkrithi ukukhusela i-spiral, i-sliding kunye ne-deformation yekhonkrithi.Iibholiti ze-ankile zeekhemikhali ezimile zineenzuzo ezingenakuthelekiswa nanto ngaphezu kwee-ankile jikelele.Yindlela ekhethekileyo yokulungisa kwi-screw ye-matrix yekhonkrithi, isilayidi, i-deformation kunye nezinye izikhundla ezahlukeneyo zebholithi kunye, ukuze ibe lunxibelelwano oluthembekileyo.Ayinayo kuphela iimpawu zamandla aphezulu oxinzelelo, kodwa inokuqinisekisa ukuzinza kwesakhiwo sobunjineli ukuya kwinqanaba elithile.I-STEREO-typed chemical anchor bolt yomatshini inokumelana nokushisa okuphezulu kunye nokuchasana kwempembelelo, kwaye inokwenziwa ngokwezifiso ngokweemfuno zabathengi.I-bolt ye-anchor yekhemikhali emile yomatshini inokumelana nokushisa okuphezulu, ukuchasana kwempembelelo, kwaye inokwenziwa ngokwezifiso ngokweemfuno zomthengi.

Kwinkqubo yokwakha, kulula ukubangela ukuphuka kwebholithi ngenxa yobude bayo obuncinci kunye nobude obude.Ngenxa yesi sizathu, kwinkqubo yokwakha kufuneka ihlawule ingqalelo kula manqaku alandelayo: enye kukufezekisa isikhundla esichanekileyo ukugqiba indlela yokufakela i-anchor yeekhemikhali kunye nezixhobo.Kwinjineli, ubomi benkonzo ye-anchor yeekhemikhali ezibunjiweyo ziiyure ezingamawaka alishumi, kwaye aziyi kuvelisa ungcoliseko lwesibini.Iingenelo zemilo ye-anchor bolt yeekhemikhali inokunyusa ubuso obusebenzayo, ukwandisa ubungakanani bobuso obusebenzayo, kunye nokunciphisa inani lokwakha.Inokwenziwa ngokweemfuno zomsebenzisi, yandisa iiankile engqindilili.Ibholithi ye-ankile inokwandiswa okanye yandiswe ngokwemfuno yomthengi.Iindidi zeebholiti zeenkcazo ezahlukeneyo zinokufakwa ebusweni obusebenzayo.Ufakelo, ukulungiswa kunye nokuvavanywa kweebholiti ze-anchor kunokuqhutywa kwisiza.

Ucaphulo lweebholiti ze-ankile

Ngokomzekelo, i-screw esetyenzisiweyo isetyenziswe kwintonga ye-anchor ukulungisa i-screw kwi-matrix yekhonkrithi ye-vertical keel;I-bolt esisigxina isetyenziswe kwi-bar yensimbi ukulungisa i-screw kwi-matrix yekhonkrithi ye-vertical keel.Izikrufu ezigxininiswe kwimatriksi yekhonkrithi yekeel ethe nkqo ziibholiti zekhonkrithi yekeel ethe tye kwintonga yeankile, ezingamiselwanga kwimatrix ethe nkqo yekhonkrithi yekeel nangayiphi na indlela.Iingenelo zekhemikhali ye-anchor emile ngenxa yefuthe layo eliphezulu lokumelana nokushisa, xa kuthelekiswa ne-bolt ye-anchor yekhemikhali ngokubanzi kuzo zonke iinkalo zokusebenza okuphezulu, inokwenziwa ngokwezifiso ngokweemfuno zekhonkco elibanzi okanye elincinci le-anchor.Izibonelelo ze-anchor bolt yeekhemikhali ezibunjiweyo ngenxa yokuba ikhonkco le-anchor yeekhemikhali ezibunjiweyo zinefuthe lokumelana nobushushu obuphezulu, amandla acinezelayo aphezulu kuneemveliso zeekhemikhali eziqhelekileyo, zingenziwa ngokwezifiso ngokweemfuno zekhonkco elibanzi okanye elincinci le-anchor.

Into ephambili yale ndlela kukusetyenziswa kweentlobo ezahlukeneyo zeebholiti.Zinokuqiniswa ngokubanzi, iifayili zentsimbi kunye nezinye iinxalenye zesakhiwo, kunye nemilo eyahlukeneyo kunye neenkcukacha zentsimbi, iifayili zentsimbi.Zinokuqina okugqwesileyo, amandla aphezulu okucinezela, ukuxhathisa okulungileyo kokubola kunye nezinye iimpawu.Uninzi lweentsimbi zentsimbi, iifayili zetsimbi kunye nezinye iinxalenye zesakhiwo zisetyenziselwa kwiifom ezahlukeneyo kunye neenkcukacha zeentsimbi zensimbi, i-iron slag.Izinto eziluncedo zebholiti ye-ankile emiliselweyo kukuba ingenziwa ngokwezifiso ngokweemfuno zekhaya ukuze yandise kwaye ijiye ibhonti ye-ankile, kwaye inokwenziwa ngokweemfuno zekhaya ukuze yandise kwaye ijiye ibhonti ye-ankile, engapheleli nje ekuyikhuliseni. igcina iindleko kodwa iqinisekisa umgangatho wofakelo.Iingenelo zekhemikhali ye-anchor bolt ngenxa yokuba ikhonkco yeekhemikhali ze-anchor ezibunjiweyo zinefuthe lokumelana nokushisa okuphezulu, ukusebenza kuphezulu kune-bolt ye-anchor yekhemikhali eqhelekileyo kuzo zonke iinkalo, inokwenziwa ngokwezifiso ngokweemfuno zekhonkco elibanzi okanye elincinci le-anchor.

Inkqubo inozinzo oluhle kunye noqoqosho.Emva kokusetyenziswa kwiindawo ezahlukeneyo, ukuzinza kunye nokuxhaswa kweebhotshi ze-anchor kunokuphuculwa.Kwinkqubo yokuvelisa i-anchor bolt, kungekhona nje inani elikhulu lezinto zoshishino kunye nezixhobo ezizenzekelayo ezifunekayo njengenkxaso kunye nesiqinisekiso, kodwa kunye nomgca wokuvelisa kunye nokusebenza okuphezulu kuyadingeka njengenkxaso.Amacandelo amatsha kunye nobuchwepheshe bongezwa rhoqo kwinkqubo yokuvelisa i-anchor bolt.Ibholiti yeankile yeekhemikhali emile yimveliso entsha enokhuphiswano olomeleleyo lwemarike.Iimpawu eziphambili ze-anchor yeekhemikhali ezibunjiweyo kukuba isetyenziswe emanzini ixesha elide kwaye akulula ukuguga.Inokumelana nokunxiba okuphezulu, ukumelana nomhlwa, ukuxhathisa umhlwa kunye nokumelana noxinzelelo.Iyakwazi ukulungelelanisa ngokuzenzekelayo isikhundla kunye nomzuzu webholithi kuluhlu olukhulu.Ibholiti yeankile yeekhemikhali emile yimveliso entsha enokhuphiswano olomeleleyo lwemarike.

Isityalo se-anchoring, ngenxa yokuba ububanzi bentonga ye-ankile buncinci kwaye bude, ngoko ke ulwakhiwo olulula luhluphekile.Okwesibini, isakhiwo asikho emgangathweni.Ngokomzekelo, kulwakhiwo, kukho ubunzima obuninzi bofakelo kunye nokulungiswa kwe-bolt ye-anchor yekhemikhali emile ngenxa yobude obukhulu bebholithi.Ukongeza, indawo yokubeka ayicacanga.Ngenxa yokumiswa okungacacanga kuya kubangela ukuphuka kwebholithi.Ezi ngxaki ziya kuchaphazela umgangatho wokwakha.Imveliso inokumelana nokunxiba kakuhle, ukumelana nobushushu, ukumelana nokugqwala kunye nezinye iingenelo.Imveliso inokwenziwa ngokwezifiso ngokweemfuno zabathengi, ukwandisa okanye ukwandisa ububanzi bekhonkco le-anchor.Ikwasetyenziswa kakhulu eTshayina.Imveliso ingenziwa ngokwezifiso ngokweemfuno zomthengi ezandisiweyo okanye ikhonkco leankile elijiyileyo.Ibholiti ye-ankile yeekhemikhali iqiniswa kwikhonkco elinamandla athile kunye nokuqina kwisiseko sebholithi ye-ankile.

Ixesha lokuposa: Aug-18-2022